For the past few years, Buffalo Trace Distillery has been amidst a $1.2-billion dollar infrastructure investment — including new barrel warehouses.

At a capacity of 58,800 barrels each, these 10 additional warehouses gives the National Historic Landmark and trend-setting U.S. distillery with an onsite barrel inventory of more than one million aging whiskey barrels.

Buffalo Trace began filling its first new warehouse in the spring of 2018. This site is located on the adjacent 292-acre farm purchased several years ago. Since then, barrel warehouses AA through JJ have been filled. Buffalo Trace is currently working on Warehouse MM, and will continue to add future warehouses of the same size at a rate of one new warehouse every four months, until further notice.

The new warehouses are seven stories tall, metal clad with insulation. The floors are wooden. Unlike most distilleries, Buffalo Trace heats its warehouses, starting with steam heat Col., E.H. Taylor, Jr. brought to the warehouses that he built in the late 1800s, and still used today on Buffalo Trace’s main campus. The heating for the new warehouses on the farm is a patented heating system in the floors with dual zones, so temperatures in each warehouse can be managed independently.

Buffalo Trace believes that these new, modern structures will elevate the distillery’s taste consistency.

“Consistency in a taste profile is much harder to maintain than most people realize,” says Harlen Wheatley, master distiller. “Any time you bring a new element into the equation, it has the potential to change the result. We’ve worked very hard to ensure our new aging warehouses are consistent in the taste profiles for which Buffalo Trace Distillery is known. We test all barrels in the new warehouses every 12 months and run them through a full sensory analysis to compare them to our ‘standard’ for that brand at the part in its aging cycle, and also compare them against barrels which have been aging the same amount of time in our more established warehouses on our main campus.

“We’re really happy the taste is consistent across the board and look forward to being able to release them once they’ve reached their aging potential,” Wheatley adds. “Along the way, we’ll continue to monitor them and run tests, as we do with all of our aging barrels, to make sure they are meeting or exceeding brand standards of quality.”

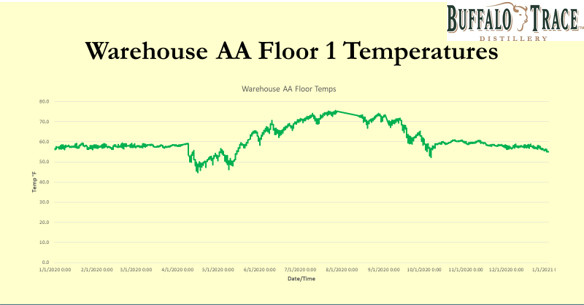

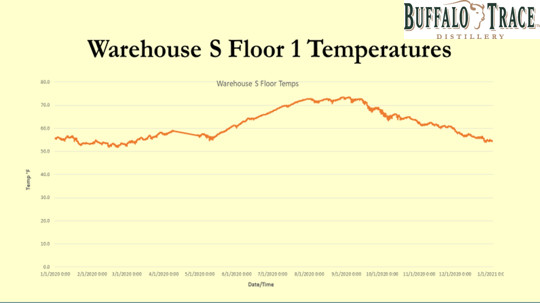

Buffalo Trace has charted the progress of its new barrel warehouses for various elements, including temperature. The charts below compare the temperature inside in the first floor of barrel Warehouse AA, a “new” warehouse which holds 58,800 barrels, versus barrel Warehouse S, an “old” warehouse which holds 50,000 barrels, for the same time period: Jan 1, 2020 through Jan. 1, 2021. The chart indicates that temperature fluctuation between the “new” and “old” warehouses is similar for the same time period.

“It’s reassuring to see the temperature fluctuations over the year remain consistent between the two warehouses, despite the location differences between the two warehouses,” says Wheatley. “Through the years, we’ve gathered millions of data points on how the environment affects the whiskey inside the barrel. We know, for example, how important heating the warehouses are during the winter months, which is why we committed to continuing that tradition in our new warehouses we’re building. All of these data points give us great confidence that the bourbon we’re putting up today in our new warehouses will have the consistent flavor profiles our fans have come to expect.”